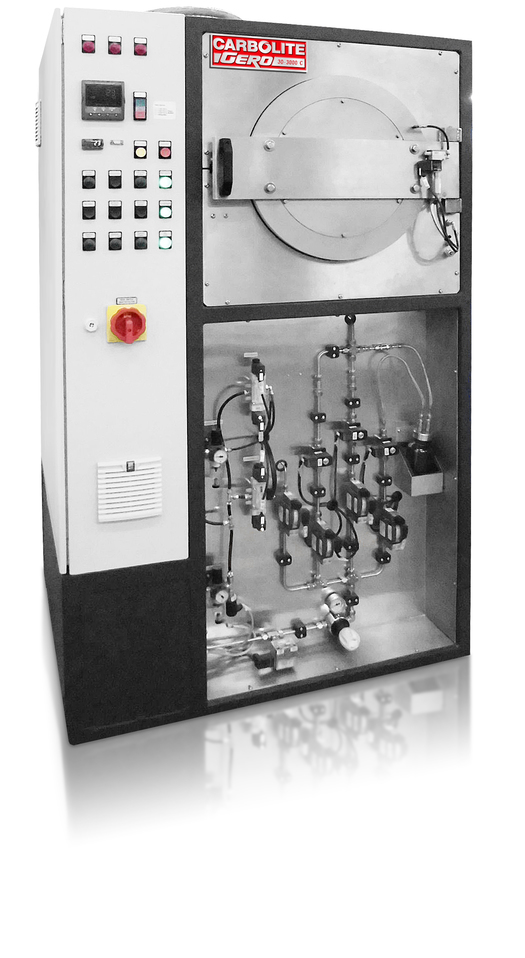

Carbolite Gero EBO

Carbolite Gero EBO debinding uuni on kehitetty erityisesti vastaamaan katalyyttisen debinding-menetelmän tiukkoja vaatimuksia. EBO on optimaalinen ratkaisu sideaineen (binder) poistamiseen (erityisesti BASF Catamold® Feedstock). Tällä uunilla voidaan saavuttaa maksimissaan 150°C lämpötila. Alla olevassa esittely videossa, on kuvattu uunin ominaisuuksia tarkemmin.

- Uuneja on kahta erilaista kokoluokkaa 120 ja 250 litrainen malli.

- Maksimilämpötila: 150 °C

- Tilavuus: 120 – 250 litraa

- Vedellä lämmitetty astia – maksimilämpötila 150°C

- Typpihapon ja typpikaasun annostelu ja kierto

Debinding prosessin kuvaus

The debinding process begins with a Nitrogen purge in order to reduce the Oxygen content in the furnace. Once the ideal process temperature is achieved gaseous nitric acid is purged into the furnace at a fixed rate. The Nitrogen gas flow must be maintained higher than nitric acid gas flow. This is done in order to prevent the system from forming an explosive mixture.

In an acidic vapour environment binder is removed from the green parts. This removal is the result of a chemical reaction starting from the surface moving inside the moulding. Debinding rates vary with the particle sizes of the metal powder and are generally between 1 – 4 mm/h. The polymer binder transits directly from the solid to the nitric acid once a temperature of 120 °C is reached.

The reaction results in formaldehyde formation as a by-product. Formaldehyde can be detected by monitoring the temperature of the EBO’s afterburner. When formaldehyde production has ended binder removal is complete. Once the EBO has detected the binder removal is complete the acid vapour environment is purged with Nitrogen. The debinding step is finished and the green parts can be transferred to a sintering furnace.